Benefits of RMT’s Horizontal Presses

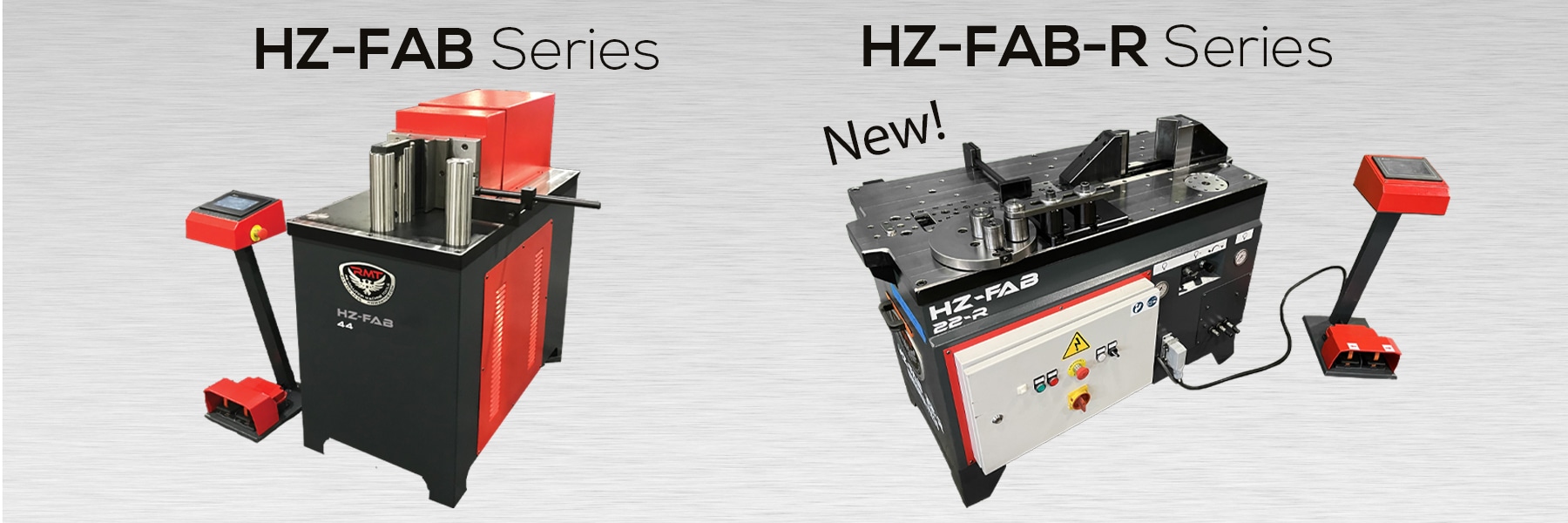

Sometimes a metalworker only needs a press brake for bending smaller parts. While a press brake bending attachment can be switched out at the punching station of many models of ironworkers, that process takes time and ties up the machine. Revolution Machine Tools’ lineup of HZ-FAB series horizontal presses are ideal for smaller metalworkers who require only 6″ to 12″ of press brake bending capacity—especially if they also need to bend tubes—and want a machine where tooling changes for different sizes and processes take only a matter of moments.

If your shop is looking for a compact, affordable solution for bending short parts, please consider these features of RMT’s HZ-FAB machines:

- Sturdy all-steel frame to withstand vigorous use

- State-of-the-art technology and high-quality components

- Operated by an NC controller

- DRO-controlled stroke adjustment

- Convenient foot pedal engagement

- Includes a brake gauge

- High repeatability, with accuracy within 1/1000th of an inch

- Comfortable working height

- Fast operation and return speeds

- Backed by a strong warranty

- Compact design—all models are less than 5′ long and 5′ high

- Heavy enough to do the job, but light enough to be moved with a forklift or pallet jack

- Includes a set of press brake tooling (hundreds of compatible dies and special tooling are optionally available to perform almost any high-pressure fabrication function)

- Induction-hardened and ground pins and tooling

- Tooling for different operations can often be switched out in a matter of seconds

- The die is supported by a heavy-duty post rather than a ram, allowing a shape to be bent completely around it without the danger of collision

- Dependable manual working system (upgradable to an automatic working system with a CNC back gauge)

While often called “horizontal press brakes” due to their primary function, these types of machines can do quite a bit more than bend shorter lengths of standard plate metal. With the right tooling, the HZ-FAB horizontal presses can also be used for multiple other functions, including:

- Angle iron bending to form a frame

- Cutting

- Hole punching

- Pipe and tube bending

- Pipe swaging

- Profile bending around a radius die

- Shaping decorative ornamental iron using laser-cut dies

- Shearing

- Step-bending curves

- Straightening

- Tube notching

The Revolution Machine Tools Advantage

In addition to the high-quality equipment offered by Revolution Machine Tools, doing business with the company itself offers many benefits not found with every equipment dealer, including such perks as:

- A Professional Sales Staff. The experienced machinery sales consultants at RMT are dedicated to finding the best solutions for every metal fabrication customer they meet. From budgetary restrictions to future growth expectations, members of RMT’s sales team evaluate all aspects of a customer’s situation to ensure a perfect fit between shop and machine. One service they provide is a site assessment to check for compatibility of the equipment they are proposing. As Revolution Machine Tools has stated, “We look at where the equipment will be placed on the production floor, how it will be brought into the facility, and even ways to make the disposal of scrap and waste easier to remove. We will also recommend the proper installation of our equipment, or we can even come install it for you. More importantly, we can verify adequate electrical, pneumatic, or hydraulic requirements and we look at the surrounding equipment to assess if there are any electro-magnetic or vibration interference issues.”

- Unparalleled Customer Service. Revolution Machine Tool’s dedication to their customers extends long after the ink is dry on the purchase agreement. From regular follow-ups to providing an array of additional services, RMT strives to build long-lasting relationships with their clientele. “They’re a good partner if you’re going to get into the business,” one fiber laser customer said about them. “At Revolution Machine Tools, it is our passion to help others succeed,” the company has stated. “We believe that manufacturing is the backbone of our economy and that by providing the best solutions to make our customers successful is how we measure our own success.”

- In-house Service and Parts Departments. Unlike some sellers who are just a storefront sales office with one or two people—or even a guy in his mom’s basement selling drop-shipped machines over the Internet—Revolution Machine Tools staffs various departments at their headquarters with personnel that can swiftly respond to the needs of their customers. Their Service Department employs factory-trained technicians able to diagnose, repair, and maintain the most complex metal fabrication equipment. Their Parts and Tooling Department stocks high-quality tooling, consumables, and replacement parts and can order any specialized tooling required by a customer.

- A Huge Variety of Equipment. Revolution Machine Tools set out to become a one-stop location for the acquisition of all products related to metal fabrication, and by the looks of things, they’ve succeeded very well. Along with their horizontal and vertical presses, they offer more than 90 models of plate rolls, nearly 60 styles of press brakes, and an extensive selection of angle rolls, fiber lasers, ironworkers, saws, shears, and more. When they notice a deficiency in the marketplace, they take it upon themselves to address it, a case-in-point being when they introduced their line of motorized 3-roll wing edge bending machines to fill the void left by the demise of the popular Farnsworth aircraft rolls. Other specialized machines they’ve developed include automatic tank bending rolls, isogrid and orthogrid forming machines, rocket fuel tank bending rolls, and wind tower bending rolls, among others. The horizontal press user who chooses to partner with RMT gains a source for the ideal equipment to supplement their bending and other fabrication work.

- A Wide Variety of Services. Revolution Machine Tools does everything it can to support its customers by offering many types of assistance that go beyond the simple sale of a machine. Some of the additional services provided by RMT include appraisals and valuations, asset recovery, auctions, consignments, financing and leasing, installation, liquidations, operator training, preventative maintenance agreements, remote support and troubleshooting, retrofitting, and taking trade-ins.

Add the Advantage of an RMT Horizontal Press to Your Shop

Starting at 11 tons of bending power and moving up to ten times that capacity, RMT HZ-FAB horizontal presses come in a range that can meet the exacting requirements of almost any fabricator. Please look over the specifications listed below, then call and talk to an RMT machinery consultant today to find the perfect horizontal press to add to your shop.

RMT HZ-FAB 11 Horizontal Press

- 11-ton maximum pressure at 200 bar

- 6″ x 0.31″ flat bending capacity

- 1.65″ x 0.12″ round tube bending capacity

- 7.2″ max. stroke

- 2.3″ bolt diameter

- 6″ tooling height

- 3′ working height

- 1’6″ L x 2’11” W table

- 3-gallon oil tank capacity

- 1.5 HP motor power

- 0.39 in/s operation and return speed

RMT HZ-FAB 22 Horizontal Press

- 22-ton maximum pressure at 200 bar

- 8″ x 0.50″ flat bending capacity

- 1.88″ x 0.15″ round tube bending capacity

- 7.2″ max. stroke

- 3″ bolt diameter

- 8″ tooling height

- 3.61′ working height

- 1’6″ L x 3’5″ W table

- 3-gallon oil tank capacity

- 3 HP motor power

- 0.39 in/s operation and return speed

RMT HZ-FAB 33 Horizontal Press

- 33-ton maximum pressure at 200 bar

- 8″ x 0.70″ flat bending capacity

- 2.36″ x 0.15″ round tube bending capacity

- 11.25″ max. stroke

- 3″ bolt diameter

- 9.75″ tooling height

- 3.61′ working height

- 2’1″ L x 4’1″ W table

- 10-gallon oil tank capacity

- 4 HP motor power

- 0.39 in/s operation and return speed

RMT HZ-FAB 44 Horizontal Press

- 44-ton maximum pressure at 200 bar

- 8″ x 1″ flat bending capacity

- 2.36″ x 0.19″ round tube bending capacity

- 11.25″ max. stroke

- 3″ bolt diameter

- 9.75″ tooling height

- 3.61′ working height

- 2’1″ L x 4’1″ W table

- 10-gallon oil tank capacity

- 5.5 HP motor power

- 0.39 in/s operation and return speed

RMT HZ-FAB 55 Horizontal Press

- 55-ton maximum pressure at 200 bar

- 12″ x 0.59″ flat bending capacity

- 2.99″ x 0.15″ round tube bending capacity

- 11.25″ max. stroke

- 3.5″ bolt diameter

- 12″ tooling height

- 3.61′ working height

- 2’2″ L x 4’1″ W table

- 15-gallon oil tank capacity

- 7.5 HP motor power

- 0.39 in/s operation and return speed

RMT HZ-FAB 88 Horizontal Press

- 88-ton maximum pressure at 200 bar

- 12″ x 1″ flat bending capacity

- 3.54″ x 0.35″ round tube bending capacity

- 11.25″ max. stroke

- 4″ bolt diameter

- 12″ tooling height

- 3.61′ working height

- 2’5″ L x 4’8″ W table

- 31-gallon oil tank capacity

- 13.5 HP motor power

- 0.39 in/s operation and return speed

RMT HZ-FAB 110 Horizontal Press

- 110-ton maximum pressure at 200 bar

- 12″ x 1.25″ flat bending capacity

- 4.48″ x 0.39″ round tube bending capacity

- 11.25″ max. stroke

- 4″ bolt diameter

- 12″ tooling height

- 3.61′ working height

- 2’5″ L x 4’8″ W table

- 31-gallon oil tank capacity

- 13.5 HP motor power

- 0.39 in/s operation and return speed

RMT offers a new horizontal press series, HZ-FAB-R Series:

RMT HZ-FAB 22-R Horizontal Press

- 22-Ton maximum pressure at 200 bar

- 6” x 0.31” flat bending capacity

- 1.9” x 0.2” round tube bending capacity

- 13.8” max stroke

- 1.6” bolt diameter

- 5.9” tooling height

- 33.5” working height

- 24.2” x 51.4” table

- 13-gallon oil tank capacity

- 1.5 HP motor power

- 0.4 in/s operation and return speed

RMT HZ-FAB 44-R Horizontal Press

- 44-Ton maximum pressure at 200 bar

- 8″ x 0.5” flat bending capacity

- 2.4” x 0.2” round tube bending capacity

- 13.8” max. stroke

- 1.6” bolt diameter

- 5.9” tooling height

- 36.6” working height

- 27.6 L x 59.6” W table

- 23-gallon oil tank capacity

- 5.5 HP motor power

- 0.4 in/s operation and return speed