Start the Presses!

It’s hardly news in the North American fabrication industry that Revolution Machine Tools provides high quality hydraulic press brakes engineered with the latest cutting-edge technology. What may be less well-known is that RMT also provides top notch hydraulic presses (minus the “brake”) throughout the industry as well.

When it comes to fabrication presses—machines used for applying great force against a metallic workpiece—they’ve been around for a good 500 years, though the printing press appeared on the scene half a century earlier, and other pressing devices go back much further in history. It was the need to readily mint coins in the first years of the 1500s that influenced the application of the earlier developed technique of the screw press to form pieces of metal.

The high-tech hydraulic presses available in the modern world from Revolution Machine Tools are constructed with durable frames of steel-welded plate and are designed to keep performing for years, even in the busiest of fab shops. Whether it’s a hydraulic press, a fiber laser, or a plate roll, Revolution Machine Tools continually provides the highest quality of components and workmanship in every metal fabrication machine they sell.

Knowing the Nomenclature

Understanding the terms associated with presses is useful for the fabricator or shop manager looking to add a metal pressing machine to his equipment lineup.

Presses can be categorized by their shape. Two popular types of presses are named after letters of the alphabet (C and H) not because of some obscure abbreviation, but simply because the frames of said machines essentially resemble the letters C and H.

The top and bottom portions of C-frame presses are connected in the back (the left side of the C), while the front and both sides are open. This design allows a great degree of operator access to the workpiece, as well as permitting the workpiece itself—even if it is long—to be positioned as needed. These machines are also known as gap-frame presses.

H-frame presses, also called H-type presses, are designed to accommodate heavier loads and get their name from their dual sidewall supports, while being open in the front and back.

The term hydraulic press refers to the power source for this common type of press, in this case a hydraulic pump. Hydraulic presses have been around since 1795, when Joseph Bramah patented the first such machine (Bramah is also famous for improving the design of the flush toilet). Other types of presses run under manual, electric motor, or pneumatic power.

While some presses might be characterized by where they are found (like a workshop press, a lower capacity H-frame press found in many shops), a large variety of press types are named after their main functions. For example, deep drawing presses are used mostly for drawing out parts into hollow shapes like cans, cylinders, and even auto body panels. These machines usually feature a main upper hydraulic cylinder and a lower hydraulically powered cylinder or cushion that move away from each other during the forming process. Other function-specific presses include coining presses, flattening presses, straightening presses, cutting presses, and blanking presses.

Other designations for presses can include types like column-frame presses (single-action presses with a hydraulic cylinder powered top plate that moves downward toward the workpiece, guided by four columns, one at each corner) and portal presses (primarily used for straightening long or large workpieces, they feature sideways traveling cylinders and frameworks that allow movement in three axes).

For machines from Revolution Machine Tools, their model numbers can indicate quite a bit about each machine at a glance. For example, any model number that begins with an “H” indicates a hydraulic press (while B is for press brake, R is for plate roll, S is for saw, and so on). Immediately following the machine type is a label like FAB or SMART. These designate series within the machine type, so an S-FAB bandsaw is good, but an S-SMART is better (in this case, semi-automatic versus automatic).

In the case of a type of machine with a wide variety of styles—like hydraulic presses—one or more letters immediately following the H-FAB or H-SMART will indicate if it is a C-frame press, one of a range of H-frame presses, a column press, or a portal press.

Models of RMT Hydraulic Presses

Revolution Machine Tools provides multiple styles and capacities of hydraulic presses to meet the most pressing needs (pun intended!) of almost any metal fabrication shop.

- H-FAB C™ Series. These C-frame single-action hydraulic presses are available in six models, ranging between 33 and 275 tons in capacity.

- H-SMART C™ Series. These touchscreen control C-frame single-action hydraulic presses are available in six models, from 33 tons up to 275 tons.

- H-FAB H™ Series. Basic H-frame workshop hydraulic presses that come in 11 models, between 65 and 550 tons.

- H-FAB HBP™ Series. These H-frame hydraulic presses are formatted to operate as press brakes and come in five models up to 330 tons.

- H-SMART HCFP™ Series. These hydraulic column-frame single-action presses are equipped with a touchscreen control panel and are available in seven models from a 110-ton version to an 1,100-ton machine, all with custom bed sizes, open heights, and strokes available.

- H-FAB HDT™ Series. These hydraulic H-frame die-cutting presses come in five models that range in capacity up to 330-tons.

- H-FAB HPP™ Series. These hydraulic portal presses are available in four models from 110 tons to 440 tons, but custom sizes up to 1,100-tons of capacity can be special-ordered.

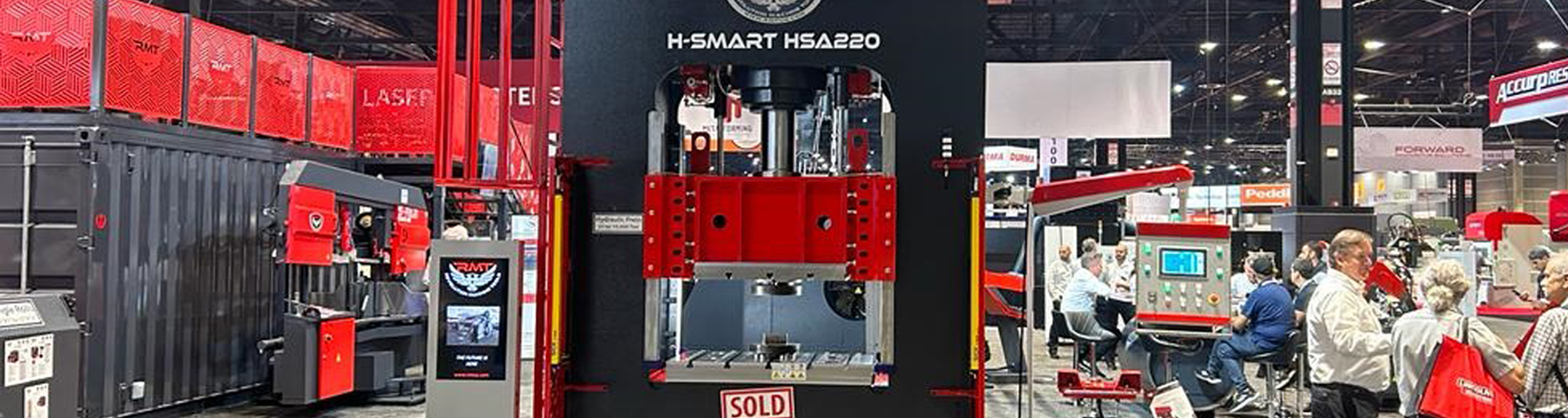

- H-SMART HSA™ Series. These deep-drawing H-frame hydraulic single-action presses feature a touchscreen control and are available in 11 standard models up to 3,300 tons, with custom sizes available.

Other specialty hydraulic presses, such as forming presses and hot plated presses, are available for special order in custom capacities up to 3,300 tons.

Benefits of Buying an RMT Hydraulic Press

In addition to cutting edge engineering and top-notch, industry-recognized components, all hydraulic presses from Revolution Machine Tools come with the same support as any other RMT machine.

A department of factory-trained technicians are only a phone call away to help troubleshoot rudimentary issues or schedule an onsite service call to assist with greater challenges (and preventative maintenance contracts are available to help save on potential service costs down the road). RMT also has an inhouse Parts and Tooling Department to supply any replacement parts or consumables that a customer might need.

Call RMT today for a competitive quote on your next hydraulic press and discover why so many customers consider them a trusted name in fabrication machine sales.

If you will be attending FABTECH 2024 this year in Orlando, Florida, please be sure to stop in at Revolution Machine Tool’s booth (S13023) to see a H-SMART HSA275, an H frame, deep drawing 275 hydraulic press, in person. Held October 15-17, 2024, at the Orange County Convention Center, FABTECH is North America’s largest metal forming, fabricating, welding, and finishing exposition.