Mastering Pipe with the Pipe Spool Master

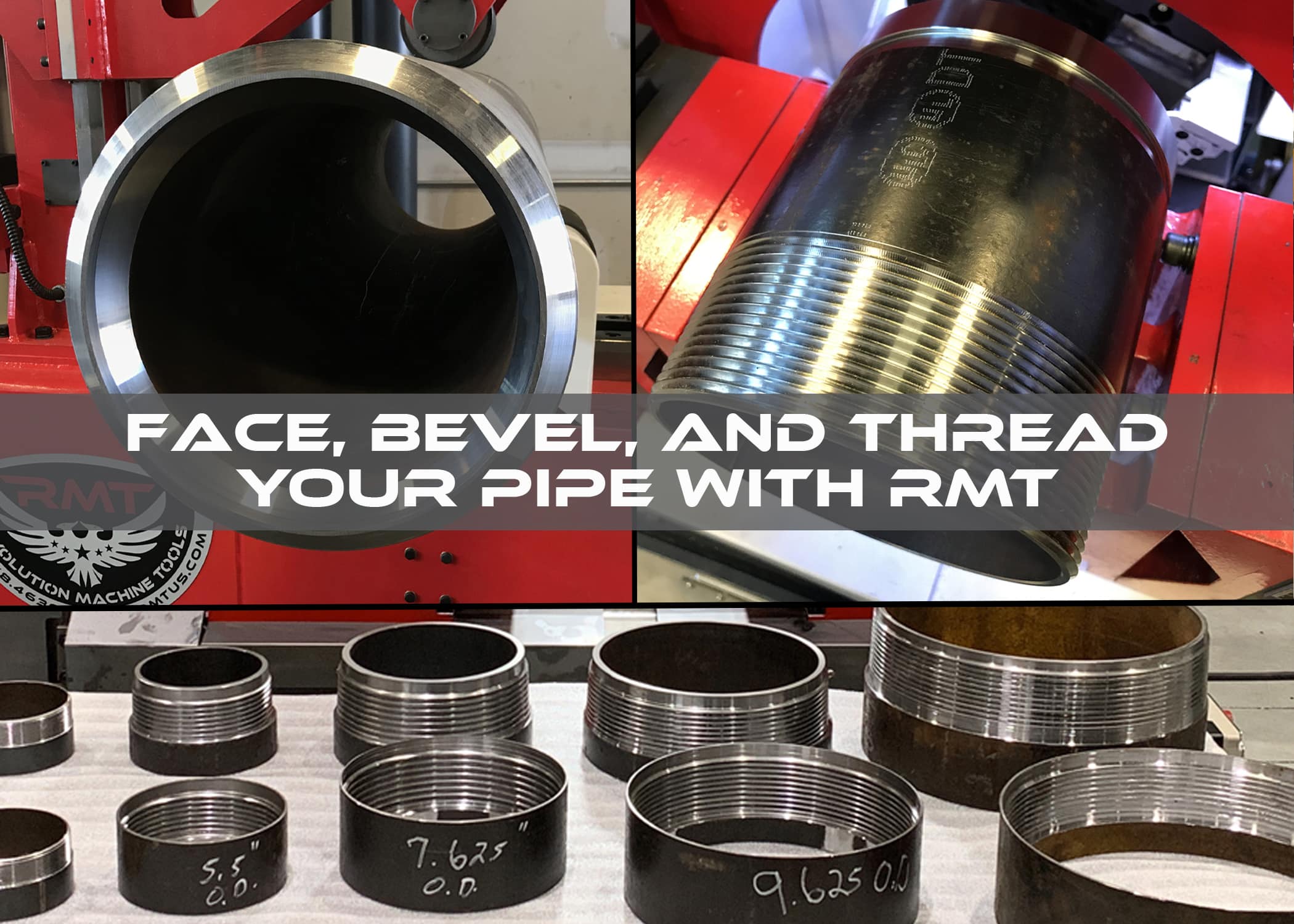

Known for years as a leader in the production and sales of top-shelf metal fabrication machines such as plate rolls and press brakes, Revolution Machine Tools entered the machining marketplace in a big way with the release in recent years of their Pipe Spool Master series of pipe facing, beveling, and threading machines. With a line-up that’s grown to 11 distinct models, RMT has a solution to meet the needs of pipe workers from plumbers to oil field maintenance personnel.

A machine identified as a “pipe spool master” would likely be very good at handling pipe spools, but what exactly is a pipe spool? In industrial settings, pipe spools refer to prefabricated sections of pipe that are assembled with fittings, valves, and other components. Pipe spools are typically fabricated off-site and then transported to the worksite for quick and efficient installation. With a Pipe Spool Master from RMT, pipe mounting companies won’t need to rely as much on third-party suppliers, being able to do much of their pipe processing inhouse themselves (and in some cases, while at the worksite!).

The magic of RMT’s Pipe Spool Master series is that they are basically “anti-lathes.” For typical work on a pipe end, like threading, the pipe is secured in a lathe and then spun at rapid speed while a tool is applied to make the desired cut. The PSM Series flips that age-old process on its head by fixing a pipe—of any length—in a stationary position, then spinning the tooling around the workpiece’s end to perform the cutting.

The original manual PSM models are beveling machines, while the CNC-equipped PSMs can additionally do boring and facing (and with a control upgrade, threading).

The PSM-E models are CNC machines specifically designed to bevel, bore, and face pipes with elbows (and thread them with an optional upgrade).

The PSM-TGB models took pipe work a bit further with included threading, plus grooving, and the traditional beveling (which is what TGB stands for). They also have the capability to do boring and facing. And a couple other processes, such as rounding and tapering. And turning, centering, milling, drilling, tapping, chamfering, texturing, and weld preparation! RMT’s PSM-TGBs are amazing multipurpose machines that are perfect for the pipe-working professional.

The RMT Pipe Spool Master Series

Revolution Machine Tools’ current entries in the pipe fitting marketplace include the following models:

RMT PSM-8 Pipe Spool Master™ is a compact manual beveling machine that can put a V bevel of any angle on a pipe or tube between 1″ and 8″ OD. A great addition for the shop working with smaller pipe.

- .28″ wall thickness capacity (one setup)

- 400 RPM maximum spindle speed

- Manual adjustment of the X-axis stroke across the facing head

- 5″ Z-axis stroke

RMT PSM-16 Pipe Spool Master™ is a manual beveling machine for creating a V bevel of any degree—such as basic 30° and 37.5° angles—on pipe or tubing between 3″ and 16″ OD using the standard vise. The ideal machine for those shops needing to bevel mid-sized pipe.

- .600″ wall thickness capacity (one setup)

- 200 RPM maximum spindle speed

- Manual adjustment of the X-axis stroke across the facing head

- 6″ Z-axis stroke

RMT PSM-32 Pipe Spool Master™ is a CNC beveling, boring, and facing machine with a standard KD CNC control, that can be upgraded for threading by substituting an optional Fanuc or Siemens control. RMT’s most popular CNC beveling machine, the PSM-32 will become the workhorse of any pipe fabrication shop with its capacity to work pipes with an OD of 6″ to 32″ (and down to 1″ with optional vise jaws).

- 3.9″ wall thickness capacity (one setup)

- 150 RPM maximum spindle speed

- 5″ X-axis stroke

- 7″ Z-axis stroke (optional upgrade to up to 24″)

RMT PSM-40 Pipe Spool Master™ comes standard with a KD CNC control for CNC beveling, boring, and facing (threading available with an upgrade to a Fanuc or Siemens CNC). The flagship of the Pipe Spool Master Series, the PSM-40 can process complex bevels in minutes on pipes from 12″ to 40″ OD with the included standard vise.

- 3.9″ wall thickness capacity (one setup)

- 150 RPM maximum spindle speed

- 5″ X-axis stroke

- 7″ Z-axis stroke (optional upgrade to up to 24″)

RMT PSM-48 Pipe Spool Master™ does CNC beveling, boring, and facing for pipe with an OD of 12″ to 48″ (and adds threading to the mix with a control upgrade).

- 3.9″ wall thickness capacity (single pass)

- 20-150 RPM spindle speeds

- 5″ X-axis stroke

- 7″ Z-axis stroke (optional upgrade to up to 24″)

RMT PSM-60 Pipe Spool Master™ performs beveling, boring, and facing functions via its standard CNC control—and threading with an upgrade to a Fanuc or Siemens CNC—on pipe with an OD of 16″ to 60″ (it can support smaller ODs such as 8″ by adding optional vice jaws).

- 6″ wall thickness capacity (one setup)

- 80 RPM maximum spindle speed

- 7″ X-axis stroke

- 7.87″ Z-axis stroke (optional upgrade to up to 24″)

RMT PSM-80 Pipe Spool Master™ is designed for CNC beveling, boring, and facing on 32″ to 80″ OD pipe, with threading available through an upgrade to a Fanuc or Siemens control unit. Users can easily program a variety of bevels in minutes, including J, U, V, C-dimension and radiused bevels.

- 4″ wall thickness capacity (one setup)

- 60 RPM maximum spindle speed

- 5″ X-axis stroke

- 7″ Z-axis stroke (optional upgrade to up to 24″)

RMT PSM-24E Pipe Spool Master™ is a CNC machine with the ability to process complex pipe bevels on elbows in minutes. The standard KD CNC control performs CNC beveling, boring, and facing functions, and threading is available with an upgrade to a Fanuc or Siemens control.

- Up to 24″ OD capacity

- 4″ wall thickness capacity (one setup)

- 50 RPM maximum spindle speed

- Powered CNC rotary indexing vice

RMT PSM-36E Pipe Spool Master™ is a CNC pipe elbow beveling machine that also performs boring and facing with the standard control and expands to threading with an upgrade to a Fanuc or Siemens CNC control.

- Up to 36″ OD capacity

- 4.72″ wall thickness capacity (one setup)

- 50 RPM maximum spindle speed

- Powered CNC rotary indexing vice

RMT PSM-TGB-14 Pipe Spool Master™ is a CNC machine for threading, grooving, beveling, and more. Able to handle pipe up to 14″ in diameter, this TGB machine can be adapted to be portable for field and on-site use.

- 20″ diameter of the facing head

- 10-300 RPM spindle speeds

- 2.75″ X-axis stroke

- 16″ Z-axis stroke (optionally expandable up to 24″)

RMT PSM-TGB-24 Pipe Spool Master™ is a CNC threading, grooving, and beveling machine that has the capacity to work with pipe with a diameter of just over 24″.

- 24.8″ diameter of the facing head (29″ swing)

- 300 RPM maximum spindle speed

- 5.5″ X-axis stroke

- 23.6″ Z-axis stroke

Larger Pipe Spool Master machines, up to 180″ OD, are available for custom order. Due to ongoing development, all specifications are subject to verification by the customer prior to purchase.

Find the Pipe Machine That’s Right for You

If you regularly bevel pipe—or do anything else with pipe ends—you need to check out these machines from Revolution Machine Tools. They are easier to set up and safer to run than traditional pipe treatment methods, and they can work with pipe of any length.

Call RMT today and talk to one of their machinery consultants and get a competitive quote on the Pipe Spool Master that would work best with your operation.