What Exactly Is a Pipe Spool?

A pipe spool is a prefabricated section of a piping system used in various industries, such as oil and gas, chemical processing, and power generation. Pipe spools are essentially segments of piping that are assembled in a controlled environment, such as a metal fabrication shop, before being transported to the installation site. This prefabrication process involves cutting, welding, and assembling pipes and fittings into a manageable length of pipe, known as a spool, which is then ready for integration into the larger piping network at the job site.

Bringing in prefabricated pipe spools from an offsite location offers several benefits over onsite production, such as:

- Greater efficiency. Prefabrication allows for parallel processing, where multiple spools can be fabricated simultaneously, reducing the overall project timeline.

- Improved quality control. Fabricating spools in a controlled environment allows for better quality control and precision compared to onsite fabrication.

- Substantial cost savings. Reducing onsite labor and minimizing the time needed for onsite installation can lead to significant cost savings.

- Increased safety. Working in a controlled environment reduces the risk of accidents and safety hazards compared to onsite welding and assembly.

- Expanded flexibility. Pipe spools can be designed and fabricated to meet specific project requirements, providing flexibility in design and installation.

Mastering the Craft of the Pipe Spool

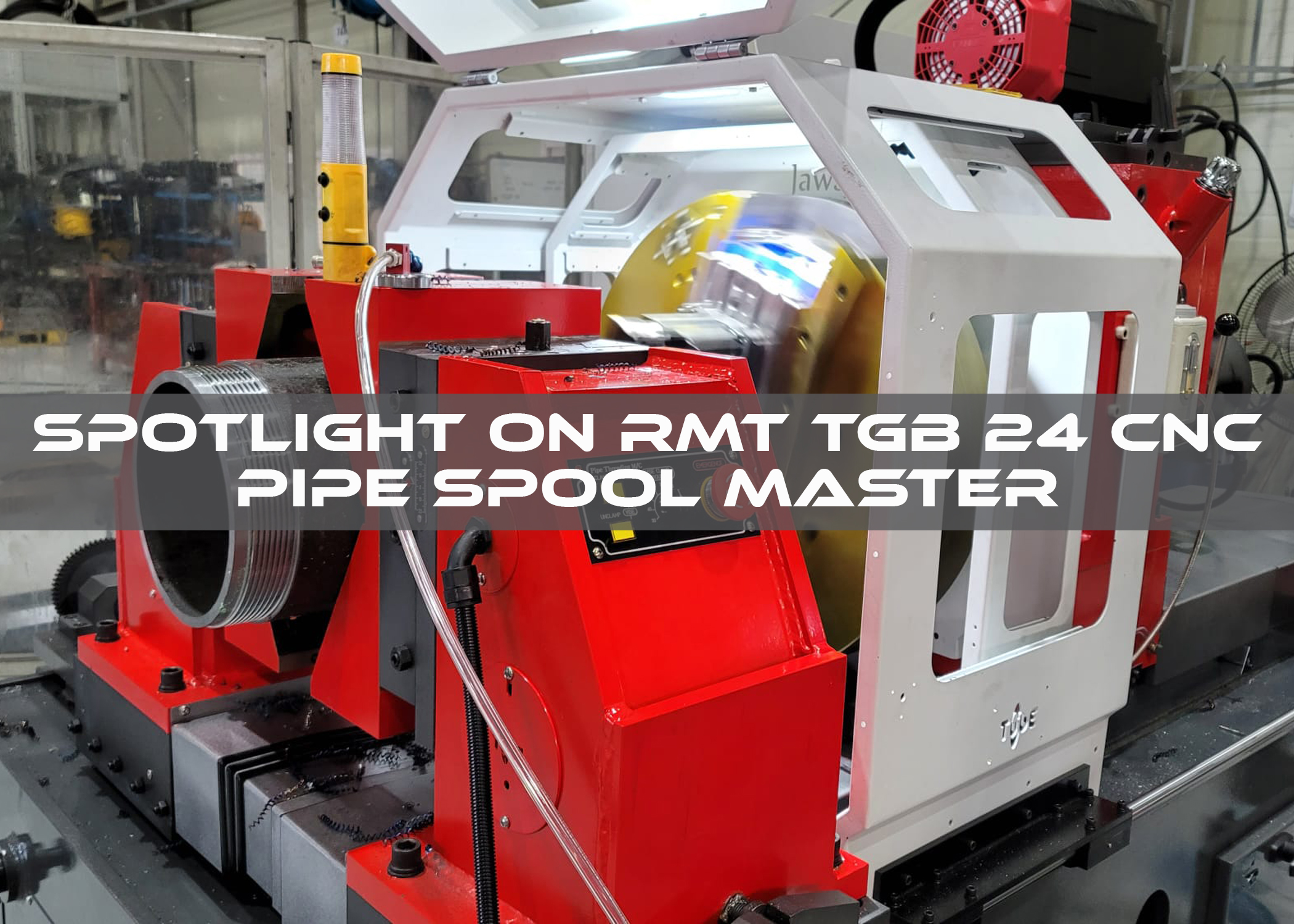

Pipe system installers can reduce their reliance on outside suppliers if they can produce their own pipe spools in-house. To assist pipe companies with this task, Revolution Machine Tools introduced the Pipe Spool Master™ series. These “reverse lathes” prepare the ends of industrial pipes by spinning the tooling around a stationary workpiece, unlike a standard lathe that spins the pipe itself while cutting it with a slowly adjusted tool. This allows them to accommodate pipes of any length. They are much easier to set up and run than traditional lathes, and since the material is not spinning, they have a much safer—and cooler—operation.

The Pipe Spool Master™ series features a wide range of capacities, from compact machines for 8″ diameter pipe to massive production units capable of processing 200″ OD pipe. The basic manual model’s bevel, while the CNC machines can also bore and face pipe (and even perform threading with a control upgrade). Specific models are designed to work with elbow segments, while the deluxe TGB machines are made to thread, groove, and bevel.

RMT TGB 24 Specification and Details

The Pipe Spool Master™ TGB 24 CNC machine has a 3″ to 24″ outside diameter capacity when equipped with the standard vice system. It has up to a 5.25″ wall thickness capacity in one setup. It sports a 15 HP FANUC main spindle servo motor and features spindle speeds from 30 RPM up to a maximum 300 RPM. Its facing head diameter is 24.8″ with a maximum swing of 29″. The X-axis stroke is 5.5″ and the Z-axis stroke is 23.6″. Weighing in at 13,000 lbs., the TGB 24 has a footprint of 112″ long by 92″ wide and is 78″ high.

The full range of threading, groove cutting, and facing is available thanks to the FANUC CNC Series 0i-TF control, which is designed for precision CNC turning. It handles standard to complex beveling, including single bevel, double bevel, single V, double V, single J, double J, single U, double U, compound J-prep, J-prep with back bevel, and compound J-prep with back bevel. Additional functions available through the control include turning, rounding, tapering, boring, chamfering, texturing, centering, milling, drilling, and tapping.

An optional follower/tracer attachment is available. Should a pipe be out of spec—round or oval—the attachment will trace the pipe to meet the customer’s specifications.

RMT’s TGB 24 processes pipe more efficiently than traditional methods, and it costs a fraction of the price of a through-spindle lathe of the size needed to accommodate an identical workpiece. It also has a much smaller footprint than an equivalent lathe since it only deals with one end of the pipe—a crane or stands can temporarily be put in place on the shop floor to support the bulk of the pipe during machining.

For anyone seeking a more compact option for threading, grooving, beveling, and more, RMT also offers their Pipe Spool Master™ TGB 14 CNC, a machine that can be adapted for field use at job sites. Able to accommodate a pipe up to 14″ in diameter, the TGB 14 CNC has a 20″ diameter facing head, a 2.75″ X-axis stroke, and a 16″ Z-axis stroke (optionally expandable up to 24″). It features variable spindle speeds up to 300 RPM.

Do More with Your Metal with Revolution Machine Tools

From prepping your pipe to bending your plate, whatever you need to do with metal, you can do it better with equipment from Revolution Machine Tools. Please give them a call today for a competitive quote on your next metalworking investment.

If you will be attending FABTECH 2024 this year in Orlando, Florida, please be sure to stop in at Revolution Machine Tool’s booth (S13023) to see the Pipe Spool Master™ TGB 24 CNC in person. Held October 15-17, 2024, at the Orange County Convention Center, FABTECH is North America’s largest metal forming, fabricating, welding, and finishing exposition.